Products

-

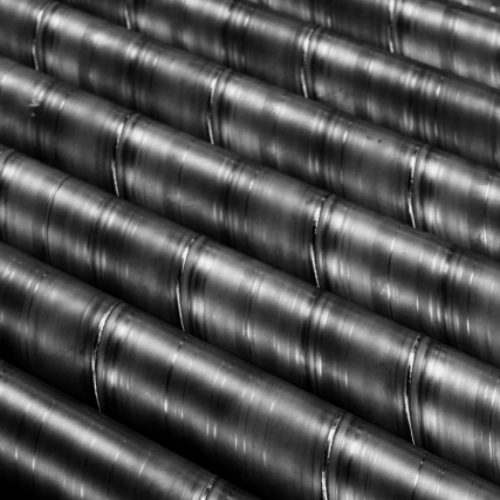

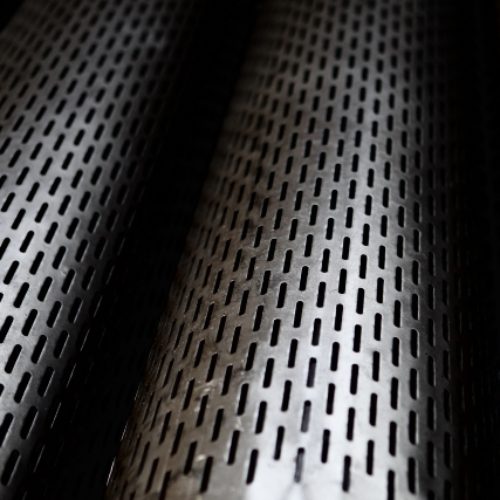

SPIRAL WELDED PIPE

Spiral welded pipes, as the name suggests, are steel pipes produced in spiral form by sewing completely by submerged arc welding method. The rolls are straightened into strips and directed to the reels to be brought into the desired form. Roll band edges bent at a predetermined angle according to the pipe diameter are optimally combined for welding.

Internal and external resources are constantly controlled throughout the production line. The welding places of the sheet metal, which is first internally and then externally joined by the submerged arc welding method, are 100% controlled by an automatic ultrasonic control system. After the roll band is in the form of a pipe, it is cut in desired lengths with an automatic plasma machine.

Product Standards

Gas and Oil Pipelines

API 5L, EN 10208, DIN 2470, ISO 3183, GOST 20295 TS 6047Water Pipelines

EN 10217, AWWA C-200, BS 534, DIN 2460, UNI 6363

DIN 1626, EN 10224, NFA 49150General Purpose Pipes

ASTM A-53, BS 3601Pile Pipes

ASTM A-252, DIN 17120, EN 10219Fittings

AWWA C-208, BS 534Product Specifications

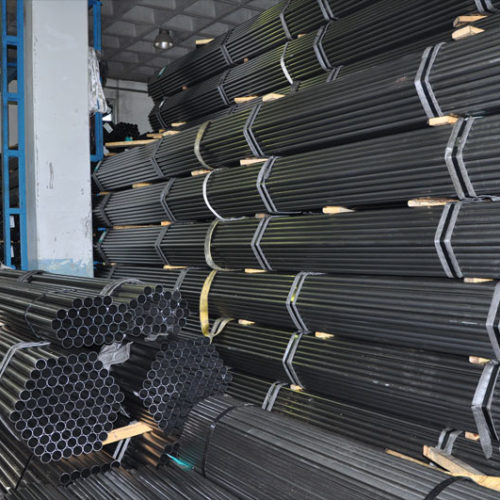

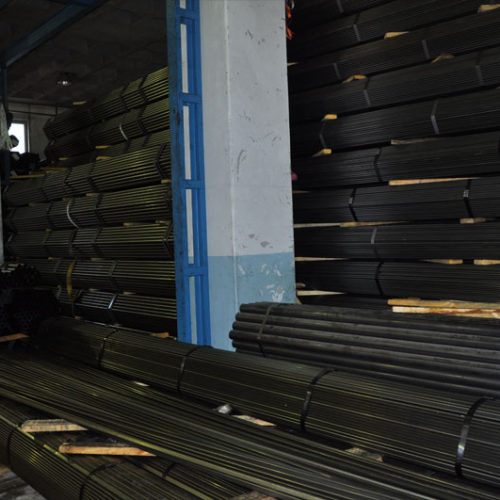

Annual Production

123,000 tonsOuter Diameter

ø219,1mm- ø3561mm (85/8”-140”)Wall Thickness

4.0mm-30.0mm (0,157”-1,2”)Pipe Length

4.0m-30.0mRaw materials

Hot Rolled CoilsWelding Process

Internal and external continuous submerged arc welding (SAW)Material Quality

API 5L (Grade A-X80), EN 10025 (S235-S355)

EN 10217 (P195TR1-P265TR2)Pipe Connection Details

Weld Beveled

Flanged Connection

Spherical Bell

Cylindrical Bell

Straight Tip -

ELBOW

-

FLANGE

-

WELL EQUIPMENT

-

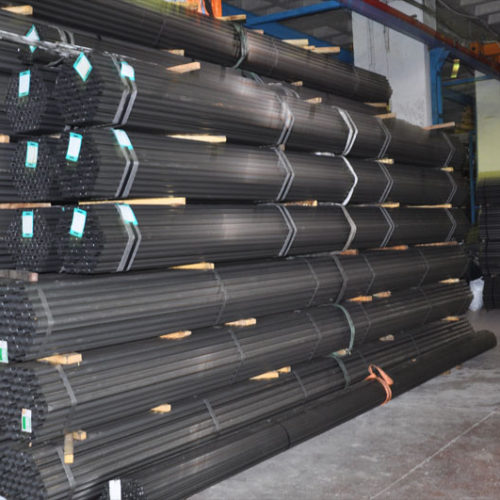

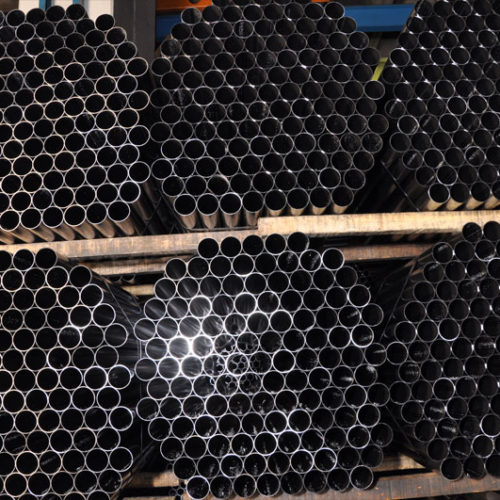

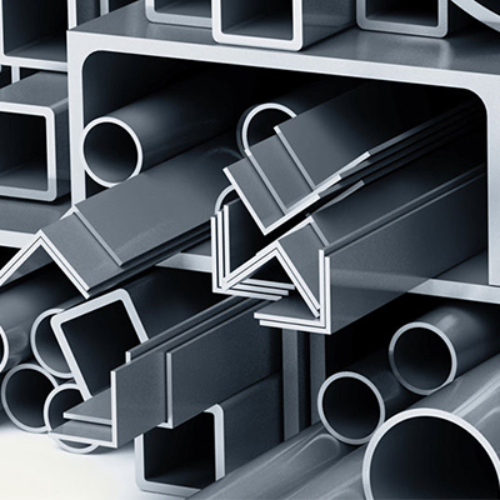

ERW PIPE

-

PROFILES